[CODE_4]: MEDIA_ELEMENT_ERROR: Format error

תמרים יעיל גבוהה תמרים קו עיבוד סירופ moleses ביצוע מכונה/la datte moleses

תמרים יעיל גבוהה תמרים קו עיבוד סירופ moleses ביצוע מכונה/la datte moleses

חלקי חילוף בחינם

חלקי חילוף בחינםHigh efficient dates syrup processing line/dates molasses making machine/la datte molasses

Description of Dates syrup processing line

Date puree processing and filling line is one of the most important food processing machines, it produces date puree from fresh dates and packs the processed date puree product in custom-made containers. It has a stable and high-speed production capacity and is characterized by being manufactured according to the quality specifications of the food industry.

Dates syrup processing and filling line

Date pulp processing and filling line is considered as one of the commercial and industrial food processing equipment, we are a food processing equipment manufacturer with technological advantages, date pulp processing and filling line is known for high quality and high production capacity, in addition, according to With a high degree of coordination of mechanical and electrical operations, the production within this line is fully automated without any human intervention.

The line offers workers an integrated protection system as it protects against current surges and also ensures an automatic stop at the end of a roll of packaging material to prevent any waste in the material.

The production line starts at the harvest stage with both wet and dry use. The wetted dates are then transferred to the peeling and tissue removal unit, which completely isolates the seeds within a virtually non-existent waste rate. This unit also chops the resulting dates. , then the product is cooled in the cooling tunnel, ready to be ground and homogenized in the homogenization unit, and then the resulting homogeneous slurry is pumped to the packaging machine through a special pump, and the slurry is packaged into thermoforming transparent bags or printing bags , The production line adopts a vacuum packaging process to ensure that the paste is not fermented and does not react with oxygen.

Characteristics of Dates syrup processing line

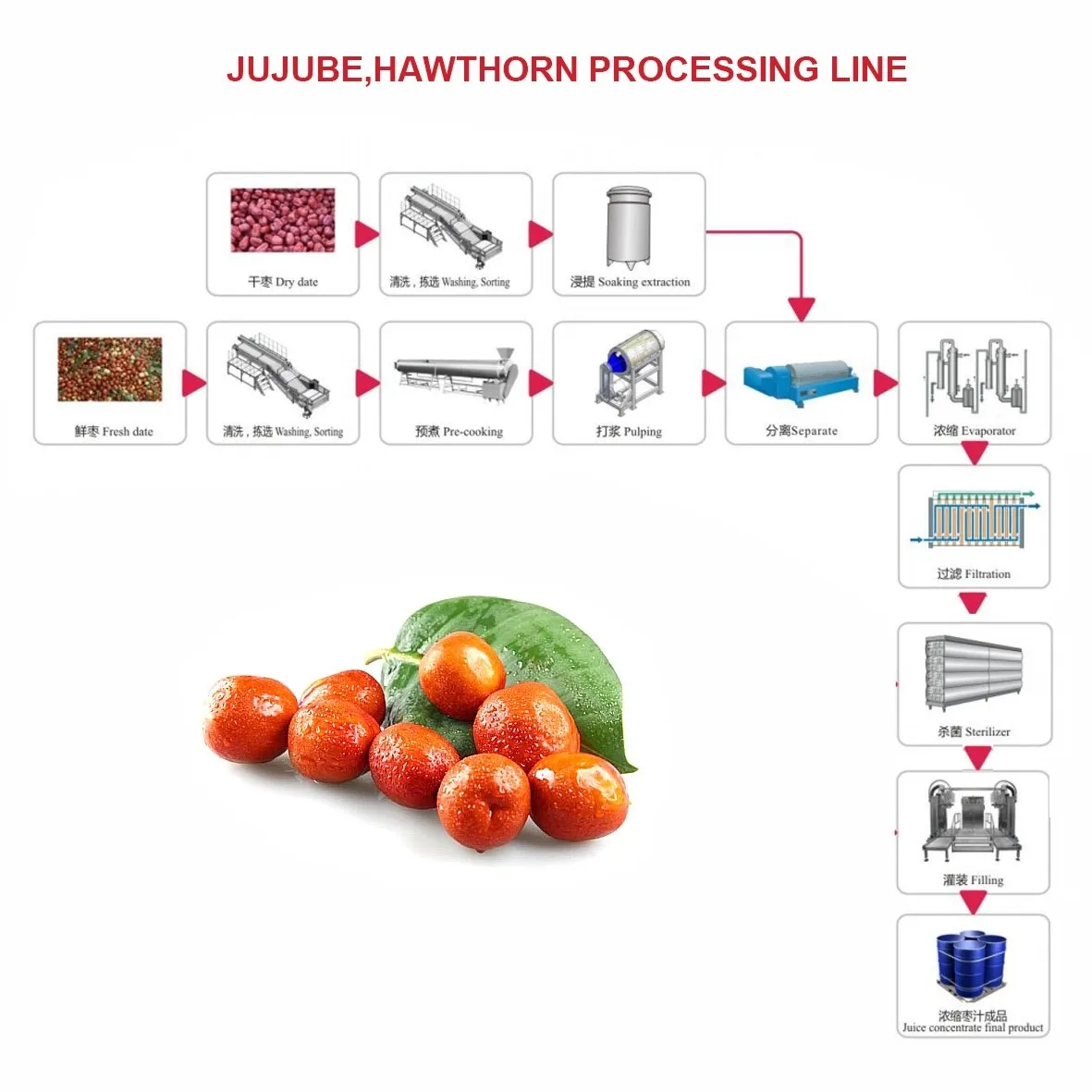

1.Wide range of raw fruits are available, this line is applicable for all kinds fruits with similar characteristic such as date, jujube, hawkthorn and so on.

2.There are two different procedures, one is immerse add extractor, another is destoner add pulper.

3.According to different investment value and product structure, client can require average, middle level or high level processing equipments.

4.End product with pure flavor, bright colour, and high material usage percentage;

5.Whole line with features as high level automatic, low labor intensity, easy operation, safe function and low operation cost.

6.Whole line adopt sanitary design, can be cleaned thoroughly, with high level sanitation.

The main equipment of the Dates Syrup processing and filling production line includes the following parts, which work together to complete the entire process from raw material processing to finished product packaging.

1. Raw material processing equipment

Cleaning machine: used for cleaning fresh or dried dates, removing dirt and impurities from the surface.

Soaking tank: Soak the jujube in water to soften it and facilitate subsequent processing.

Crusher: Crush the soaked jujube into small pieces for easy juice extraction.

2. Extract equipment

Juicer: Squeeze out the juice from the crushed jujube pieces through mechanical pressure.

Filter: Use a filter or centrifugal separator to remove solid residue from the juice and obtain clear jujube juice.

3. Concentrating equipment

Evaporator: Evaporates the water in jujube juice by heating, and concentrates it into syrup. Multi effect evaporators or vacuum evaporators can be used to improve efficiency and reduce energy consumption.

• Cooler: The concentrated syrup needs to be cooled to a suitable temperature for subsequent processing.

4. Filling equipment

Filling machine: Automatically fill syrup into bottles or other containers according to product specifications. Common filling methods include gravity filling, pressure filling, and metering pump filling.

Sealing machine: Seal the filled bottles to ensure the sealing and shelf life of the product. Common sealing methods include screw caps, pressure caps, and heat seals.

5. Labeling and packaging equipment

Labeling machine: automatically attaches labels to the bottle body, identifying brand, production date, ingredients, and other information.

Packaging machine: Combine a single bottle or multiple bottles into a box for outer packaging. Common packaging methods include cardboard boxes, plastic pallets, etc.

Stacking machine: Stack packaged boxes into pallets for easy transportation and storage.

6. Testing and quality control equipment

Metal detector: detects whether there are metal impurities in the product to ensure food safety.

Weight detector: Check whether the net content of each bottle of syrup meets the standard.

Visual inspection system: using cameras and image processing technology to detect the integrity of labels, seals, and packaging.

7. Auxiliary equipment

Conveyor belt: connects the material transfer between various processes to ensure the continuity of production.

• Storage tank: stores intermediate and finished products, such as raw jujube juice, concentrated syrup, etc.

CIP (Clean in Place) system: an online cleaning system used to clean and disinfect production equipment to ensure hygiene standards.

Example device configuration

1. Cleaning machine

• Function: Efficient cleaning, strong stain removal ability

• Capacity: 1 ton/hour

2. Juicer

Function: High pressure juicing, high extraction rate

• Capacity: 2 tons/hour

3. Multi effect evaporator

• Function: Efficient concentration, energy-saving and consumption reducing

• Capacity: 3 tons/hour

4. Automatic filling line

• Function: Precise filling, multiple capacity options

• Production capacity: 4000 bottles/hour

5. Sealing machine

Function: Quick sealing, good sealing performance

• Production capacity: 5000 bottles/hour

Through the above equipment configuration, a complete jujube syrup processing and filling production line can be built to meet the needs of various links from raw material processing to finished product packaging.

Development of every new technology ,is in order to meet the customer's need!

|

Raw material: |

All kinds big date, small date, jujube, dry date, fresh date and hawkthorn |

|

End product: |

juice Concentrate, transparent juice, cloudy juice, sea-buckthron oil |

|

Production capacity: |

20T/D-2000T/D |

|

Output percentage: |

≥90% |

|

Solid content |

7~12Brix |

|

Packing type for end product: |

Aseptic Bag/glass Bottle/PET Bottle /gable Top Box |

Dates syrup processing line can use fresh date or dry date as raw material, by washing, destoner and pulper to produce juice or paste or syrup.The equipments include: washing , sorting and inspection, precooking and pulping, separate and filtration and concentration etc.

Surfing washing machine

Description:

This machine produces water bubble by air blower to wash the fruits; the machine is composed of water cabinet, feeding device, fan etc.

Application:widely used to gently wash the fruits & vegetables

The lifter matched is made of SUS304 stainless steel or plastic material, extra water spraying device can be fixed on the machine.

Characteristics:

1.During the washing procedure, under the motivity of water current and bubble, the fruits or vegetables circumvolve without fixed direction be washed thoroughly, salts and pesticide that remain on will be removed at the same time;

2. Fruits & Vegetables are pushed to the steel roll elevator by spouted water under compressed air, then turn the next processing step;

3. The Used water can be recycled after filtration;

4. The capacity of this equipment is changeable as the motor of engine is equipped with step-less shift gears.

The process of customizing the Dates Syrup production line can be roughly divided into the following steps:

1. Requirement analysis: Firstly, we need to have a detailed understanding of your production requirements, including expected output, degree of automation, budget range, space constraints, as well as product characteristics and quality standards. This step will help us tailor the most suitable production line solution for you.

2. Scheme design: Based on the collected demand information, our engineering team will design the layout and process flow of the production line. This includes the specific equipment configuration and technical parameters for key processes such as cleaning, de nucleating, crushing, boiling, filtering, concentration, filling, sealing, and packaging.

3. Technical discussion and confirmation: We will have a detailed technical discussion with you, explaining the working principle of each link, the reasons for equipment selection, and the expected effects. During this period, you can provide modification suggestions until the plan meets all your requirements.

4. Quotation and Contract Signing: After the plan is determined, we will provide a detailed project quotation, including equipment costs, installation and commissioning costs, training costs, etc. After both parties reach an agreement, sign the formal contract.

5. Production and Delivery: After the contract takes effect, we begin the production and manufacturing of the production line. At the same time, we provide you with a production progress report to ensure that the project progresses on time. After the equipment is manufactured, arrange logistics transportation to the designated location.

6. Installation and commissioning: Our technicians will go to the site to carry out equipment installation and commissioning work, and provide training to the operators to ensure that the production line can operate smoothly and achieve the expected production efficiency and product quality.

7. After sales service: After the production line is put into operation, we will provide a certain period of warranty service and technical support to ensure that any problems you encounter during subsequent use can be resolved in a timely manner.

Pre sales services

Post sales services

1. Equipment warranty period: We provide a one-year free warranty service for mechanical equipment. If any non-human caused problems occur during the warranty period, we will provide free repair or replacement services.

2. Maintenance and upkeep services: We provide regular or irregular equipment maintenance and upkeep services to ensure the normal operation of the equipment. We will provide 24-hour online technical support services.

3. Accessory supply: We guarantee to provide original factory accessories in a timely manner in case of equipment damage or replacement of parts.

4. Training services: In order to enable customers to effectively operate and maintain equipment, we will provide equipment operation and maintenance training.

5. Installation and debugging: We will provide equipment installation and debugging services to ensure that the equipment is installed correctly and can operate normally.

1 ) Q: How can we visit your factory?

A: If you come from abroad, air to shanghai airport, then we can pick you up at airport.

2) Q: How do you ensure the quality of your products?

A: Our Company is a state owned enterprise with more than 16 years experience , strict operation policy is performed, advanced processing machines guarangtee the precision of all components, workers with operation license, parts get multiprocessing, transmission& electrical parts are of international famous brand. Series of test and inspection are done in the whole producing state.

3) Q: What payment methods your company accept?

A: We accept most of the payment methods , but mainly accept T/T, L/C at sight .

4) Q: How long is the warranty time for your products?

A: Our officially promised warranty time is 12 months after commissioning .

5) Q: I am new in this field,can you supply us turnkey services?

A: YES.We can supply all the system including Market Analysis/Product Analysis/Location Choice/Processing Flow Design/Equipment Layout Design/Building Design direction/Equipment mode selection/Equipment Manufacturing/Equipment Mounting/Equipment Debugging/Worker Training.

6) Q: I haven't done business with you company before, how can I trust your company ?

A: Our company has been in Cooig.com for 14 years, which is longer than most of our fellow suppliers, we have been golden suppliers for years. What ' s more, we have got quite a lot authority certificates, for example, CE, ISO9001, Cooig onsite check certificate.

7) Q: What ' s the shipment terms and delivery time of your company?

A: Well, the delivery time depend on the quantity of your order. Usually is 20 days . For some customized machine 30 days is necessary.

8) Q: Can you supply OEM services?

A: Yes,we have our R&D team,and we have more than 400 workers with workshop area 75000 square meters.

9) Q: Do you give any Discount?

A: I will surely try my best to help you get those by the best price and good service at the same time.

כל תשלום שאתם מבצעים ב-Cooig.com מאובטח על ידי הצפנת SSL ופרוטוקולי PCI DSS קפדניים להגנה על נתונים

דרשו החזר כספי אם הזמנתכם אינה נשלחת, אובדת או מגיעה עם בעיות במוצרים