[CODE_4]: MEDIA_ELEMENT_ERROR: Format error

The CHT series of fully automatic video measuring machines covers a wide range of measurement scales. Employing a granite base, a precision servo control system, and an optical motorized zoom lens, it achieves high-precision measurements. The CHT series boasts powerful functionalities, capable of precisely measuring various complex parts' surface dimensions, contours, angles, positions, and form and position tolerances.

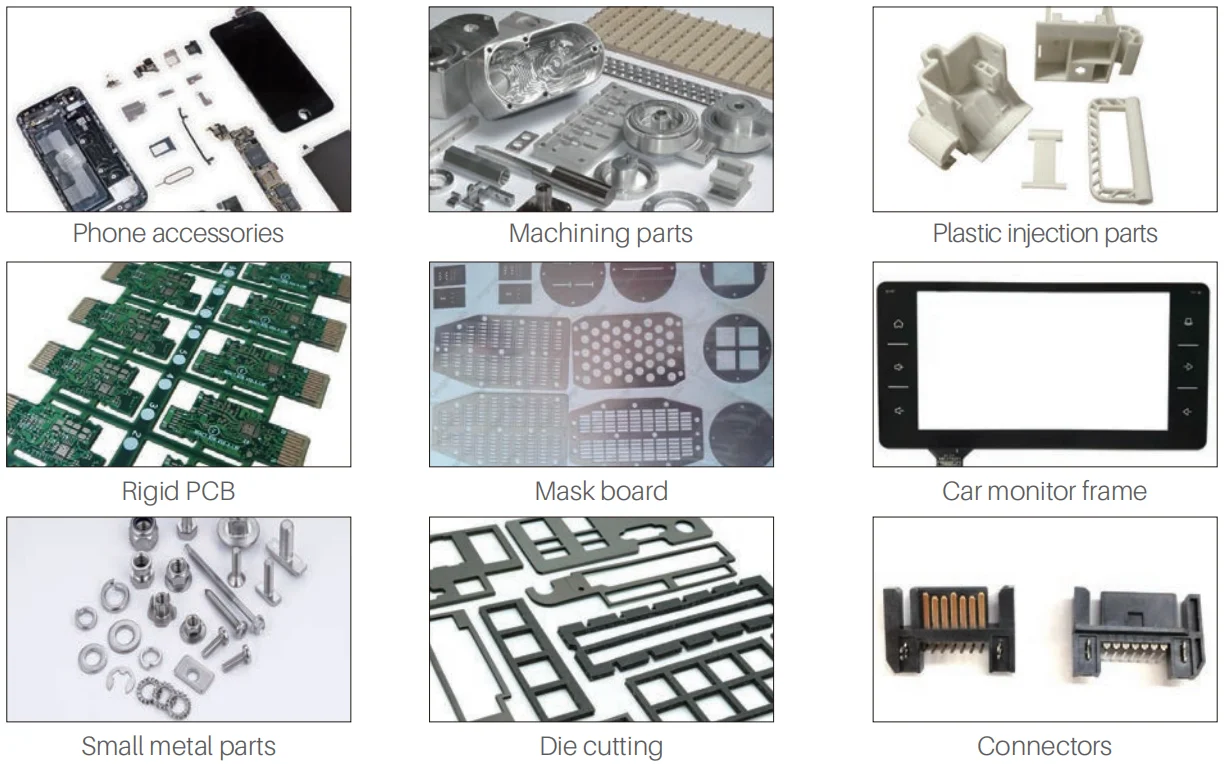

The CHT series of fully automatic video measuring machines finds extensive applications in numerous industries, including machinery, electronics, mold manufacturing, injection molding, hardware, rubber, low-voltage electrical appliances, magnetic materials, precision stamping, connectors, terminals, mobile phones, home appliances, printed circuit boards, medical devices, watches, cutting tools, and metrology testing.

| Model No. | CHT322S | CHT432S | |

| Travel Range | X(mm) | 300 | 400 |

| Y(mm) | 200 | 300 | |

| Z(mm) | 200 | 200 | |

| Structure Type | Column | ||

| Base Material | Marble | ||

| Monitor | 24" LCD(1920×1080) | ||

| Image Sensor | 1.6MP High definition colorful industrial camera | ||

| Resolution of Glass scale | 0.1μm | ||

| Lens | 13.3X motorized lens | ||

| Magnification *1 | Optical Zoom: 0.6X~8.0X, Image Zoom: 17~380X | ||

| Light | Back light | Telecentric transmission illumination | |

| Ring Light | 6 rings and 8 segments (256 levels) surface light( or RGB surface light, Optional) | ||

| Coaxial Light | LED | ||

| Accuracy*1 | X/Y | (1.8+L/200)μm | |

| X⊥Y | (2.2+L/200)μm | ||

| Z*2 | (3.0+L/200)μm | ||

| 3D Scanning *3 | Z measuring range *4 | 5mm | |

| Scanning width *5 | 30mm | ||

| Repeatability *6 | ±1μm | ||

| Meas. Accuracy *6 | ±0.1%F.S. | ||

| Fly-Shooting Mode | Support | ||

| Navigation Camera | Support | ||

| Sensor Option | (1)Touch probe; (2)Laser probe | ||

| Max Speed | XY(mm/s) | 500 | |

| Z(mm/s) | 100 | ||

| Size(mm) | 760×1220×1670 | 860×1350×1670 | |

| Weight(kg) | 600 | 650 | |

| Loading Capacity(kg) | 25 | ||

| Power | 1500W | 2000W | |

| Motion Control | Servo control system | ||

| Software | InsightX | ||

| Input | 200-240VAC, 50/60Hz | ||

| Working Environment | Temp.20℃ ±2℃ , Humidity 20~80%, Vibration<0.002g, Less than15Hz | ||

| Note: *1 In the focus position, the environment temperature is +20 °C ± 1.0 °C, and the load on the table is 5 kg or less; L is the moving range of the table in mm. *2 It is mechanical accuracy, and actual accuracy depends on object surface where lens focuses. *3 Optional line-scanning probe is required. *4 Measuring range 5mm~40mm optional. *5 Scanning width 30mm~145mm optional. *6 Environment temperature is +20°C ± 1.0°C. |

|||

Stabilize the mobile platform structure

1.Precision marble machine, good stability.

2.Precision linear slide rail and servo control system to ensure system accuracy.

3.Three-axis automatic programmable detection, to achieve batch detection of complex features.

Flexible shooting and accurate calculation

1.High-resolution electric zoom lens, taking into account the measurement efficiency and accuracy.

2.Support segmented programming control of surface light, transmitted light, and coaxial light.

3.Automatically identify the measurement site, and obtain unified and stable measurement results every time.

4.The advanced algorithm has been certified by the PTB German Federal Institute of Physics and Technology.

Automatic measurement, faster batch processing

1.The program matches the coordinate system of the workpiece and automatically performs the measurement process.

2.Support the import of CAD drawings and Gerber drawings, and the coordinate system matches the measurement.

3.In the CNC fixed coordinate system mode, batch measurements can be made quickly and accurately.

Rich accessories, a variety of composite measurements

1.Support trigger probes and optical probes for height and flatness measurement, and realize 3D spatial measurement.

2.Support external input such as calipers and altimeters, and centralized data management.

3.Support label printers.

Simple operation, easy and worry-free

1.Anyone can get started quickly without complicated training.

2.With a simple user interface, anyone can easily set up and measure.

3.Generate statistical analysis, test result reports, etc. with one click.

The software is feature-rich and automatically reports

1.Provide up to 80 kinds of feature extraction, auxiliary structure, intelligent labeling, shape and position tolerance, special applications and other analysis tools.

2.Automatically output SPC analysis reports, support Q-DAS transmission, and support remote data docking.

Software Functions

Measurement function

1.Measurement tools: scanning to extract edge points, multi-segment extraction of edge points, circular extraction of edge points, ellipse extraction, frame selection to extract contour lines, focus points, nearest points, etc.

2.Measurable geometric quantities: point, line, circle (center coordinates, radius, diameter), arc, center, angle, distance, line width, hole position, aperture, number of holes, hole-to-hole distance, hole-to-edge distance, arc center-to-hole distance, arc center-to-edge distance, arc high point to arc high point distance, intersection point to intersection point distance, etc.

3.Construction features: intersection point, center point, extreme point, end point, two-point connection, parallel line, vertical line, tangent line, bisector line, center line, line segment fusion, radius circle, three-line inner tangent circle, two-line radius inner tangent circle, etc.

4.Shape and position tolerances: straightness, roundness, contour, position, flatness, symmetry, verticality, concentricity, parallelism and other shape and position tolerance assessments.

5.Coordinate system: instrument coordinate system, point-line, two-point X, two-line and other workpiece coordinate system; image registration coordinate system; the coordinate system can be translated, rotated, and manually adjusted.

6.Quick tools: R angle, horizontal pitch, circular pitch, screen, slot, contour comparison, spring, O-ring and other special tools for quick measurement.

7.Support batch setting of tolerances, proportional grading, and color customization management.

AI automatic edge finding technology

1.The AI model training interface is simple, the algorithm is powerful, the training ability is strong, and the training data is intuitive.

2.The AI measurement software can save pictures while measuring, continuously optimize and iterate the AI model, and has high efficiency.

3.It can solve traditional measurement pain points such as blurred boundaries, multiple boundaries, too many burrs, and too much edge interference.

4.Compared with traditional manual measurement, it has high efficiency and good repeatability.

3D offline programming

1.Import 3D data offline for measurement program editing to improve measurement efficiency.

2.The interface is intuitive, simple to operate, easy to learn and easy to use.

Record management function

1.Centralized management of all measurement records.

2.CNC measurement supports scan code gun input.

3.Query by workpiece model, workpiece name, inspection date, workpiece identification code, etc.

Data output function

1.Can output Excel, Word, TXT reports.

2.Support the import and export of AutoCAD files.

3.Support real-time output to excel templates, and templates can be customized.

4.Output SPC analysis report, can output statistical values (such as CA, PPK, CPK, PP, etc.) and control diagrams (such as mean and extreme difference diagrams, mean and standard deviation diagrams, median and extreme difference diagrams, single-value and moving extreme difference diagrams).

Support Q-DAS transmission, support customized remote data docking

Chotest Technology Inc.

Chotest Technology Inc.

CHOTEST is a national high-tech enterprise integrating research, development, production and sales. Committed to the design and production of precision measuring instruments and calibration instruments.Since the company established, we insist on technological innovation as the basis of development. With more than15 years of development, our company has accumulated rich practical experience and established a strong professional technical team in optics, mechanics, electronics and information technology, also owns a number of technology patents and software intellectual property rights. We have unique designing and manufacturing advantages in Micro-Nano motion, 3D Reconstruction of Micro-Nano measurement, 3D Form and Surface Analysis of Micro-Nano measurement, Large-scale 3D Measurement, Precision Sensing Probe, Control & of Glass-Scale and Guide Rail etc. That is why we have ability to provide our customers with professional precision measurement solution from nano meter to hundred meter.

At present there are over 600 employees in our company, we got modern office in Nanshan, Shenzhen and precision machining & assembly factory in Baoan, Shenzhen. In addition, we also built a number of professional laboratories with advanced research facilities. All products are manufactured in accordance with ISO9001, 6S standard and always provide customers with top quality products.The sales network and service outlets of our company have covered more than 30 provinces in China, in the meanwhile our overseas market is also growing fast.

With more than 15 years of professional technology accumulation, we designed and manufactured White Light Interferometer SuperView W1, Laser Tracker GT series, Universal Thread Measuring Machines SJ5200 series, Universal Length Measuring Machines SJ5100 series, Laser Interferometer SJ6000, Profilometers SJ5700 series, Automated Dial Indicator Testing Machines SJ2000 series and other high-end measuring equipment. We provide high precision measurement solution from nanometer to hundred meters.Our products has been used widely in government Metrology and Quality Inspection agencies, automotive, aerospace, machinery, metallurgy, electric power, petrochemical and other industries.CHOTEST focuses on technology development & innovation of precision measurement equipment and sophisticated testing equipment with motto of Self-Discipline. Our goal is to provide high-end measuring equipment to manufacturing industry all over the world.

כל תשלום שאתם מבצעים ב-Cooig.com מאובטח על ידי הצפנת SSL ופרוטוקולי PCI DSS קפדניים להגנה על נתונים

דרשו החזר כספי אם הזמנתכם אינה נשלחת, אובדת או מגיעה עם בעיות במוצרים